Effect of Berry Density and Cuticle Integrity on Post-Drying Texture in Mavis Raisins

Have you ever wondered why some Mavis raisins turn out soft and chewy while others dry into hard, brittle pellets? This isn’t a random outcome—it often traces back to two invisible but powerful factors: berry density and cuticle integrity. Understanding how these properties affect post-drying texture gives producers a competitive edge in the high-stakes export market.

This article explores how berry compactness and skin structure influence the texture of Mavis raisins, offering practical insights to optimize consistency and reduce processing loss.

Why Berry Density Matters in Raisin Texture

Mavis raisins, derived from the Shahani grape variety, are known for their large, juicy berries. But with larger size comes greater variability in internal structure and density. Berry density refers to the mass-to-volume ratio of a grape and directly influences how moisture escapes during drying.

Denser berries tend to trap internal moisture for longer. When placed closely together, these berries slow the airflow around them, creating microenvironments of high humidity. This leads to incomplete drying in some areas and over-drying in others. The result is a batch of raisins with inconsistent firmness, affecting shelf life and mouthfeel.

Cuticle Integrity as a Moisture Barrier

The grape cuticle, a thin layer of waxes and polymers on the fruit’s surface, plays a protective role during the drying process. When intact, it slows moisture loss, resulting in more gradual dehydration. This delay allows sugars to concentrate evenly, giving raisins their signature chew.

However, any cracks, thinning, or damage to the cuticle—whether from mechanical harvesting, poor handling, or pretreatment—compromises this barrier. Damaged cuticles accelerate moisture escape, causing the outer skin to harden while the core remains sticky or under-dried.

In Mavis grapes, whose skin is thicker than most seedless varieties, minor damage can have amplified effects due to their size and sugar density.

Combined Impact of Density and Cuticle on Final Texture

When high-density berries with compromised cuticles are dried in bulk, they exhibit uneven texture. The outer skin may collapse or toughen, while the inside retains too much water. This imbalance is a major cause of customer complaints and failed export inspections.

Even with ideal drying conditions, berries in the center of tightly packed trays receive less airflow and heat, especially if their cuticles are intact and unbroken. This leads to a mix of soft, ideal-texture raisins and others that are brittle or rubbery.

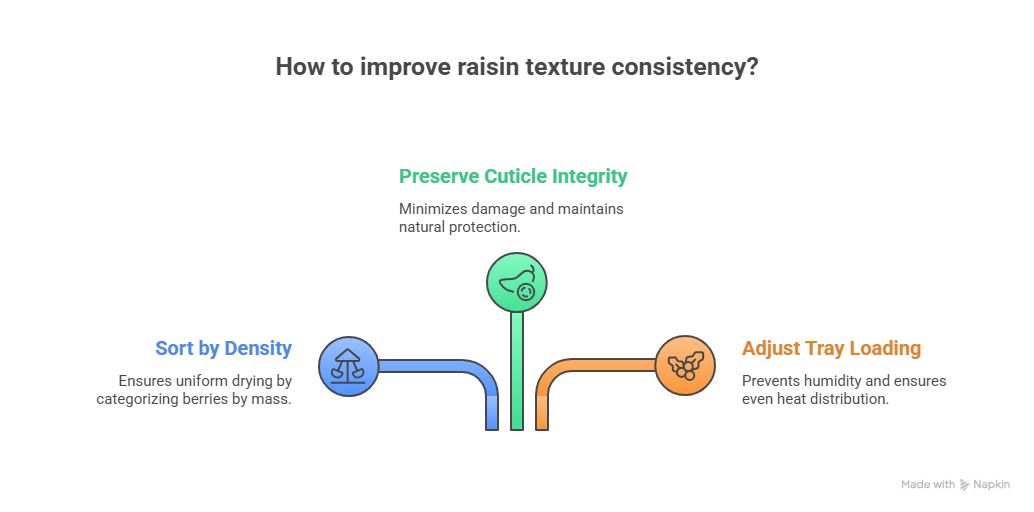

Three Steps to Improve Raisin Texture Consistency

1. Sort Grapes by Density Before Drying

Use floatation or optical sensors to categorize berries by mass. Dry similar-density berries in separate batches.

2. Inspect and Preserve Cuticle Integrity

Minimize handling damage. Avoid excessive mechanical pressure and use gentle pretreatments that preserve cuticle function.

3. Adjust Tray Loading to Control Airflow

Reduce tray density and increase spacing to prevent trapped humidity and uneven heat distribution during drying.

FAQ: Berry Texture and Raisin Quality

What is berry density and why does it matter in raisins?

Berry density is the ratio of a grape’s weight to its volume. Denser berries hold more moisture, affecting how evenly they dry.

How does the grape cuticle influence raisin texture?

The cuticle slows water loss. If it’s damaged, moisture escapes too quickly, causing outer hardening and inner softness.

Can poor texture in Mavis raisins be fixed post-drying?

No. Texture issues due to density or cuticle damage are best prevented before or during drying. Rehydration methods have limited success.

Why are some Mavis raisins chewier than others?

Chewy raisins often come from moderate-density berries with intact cuticles, which dry slowly and evenly.

Is sorting berries by size enough to control texture?

Size sorting helps, but density and cuticle condition are more precise indicators of drying behavior and texture outcomes.