Effect of Alkali Concentration on Drying in Sultana Raisins

How Alkali Pre-Treatment Influences Raisin Drying Efficiency

Sultana dark raisins, known for their light color and soft texture, undergo a critical transformation during drying. A key factor influencing this process is the concentration of alkali solution used in the pre-treatment phase. This pre-treatment alters the grape’s skin structure, enhancing moisture evaporation and directly affecting drying time, uniformity, and final quality. By understanding the effect of alkali concentration on drying in Sultana raisins, producers can optimize processing for consistency, reduced energy usage, and superior product quality.

What if a simple change in concentration could significantly improve your drying efficiency and color retention? That’s what science shows—and it begins with the grape skin.

Why Grape Skin Permeability Matters in Drying

Sultana grapes have a naturally waxy cuticle that resists water evaporation. This becomes a bottleneck during the drying stage. Pre-treatment with alkaline solutions like potassium carbonate softens and breaks down this barrier. The result is increased permeability, allowing moisture to escape more quickly and uniformly across the batch.

Without this treatment, grapes dry at inconsistent rates, leading to texture variation, color degradation, and higher production costs due to extended drying cycles.

Understanding the Role of Alkali Concentration

Different alkali concentrations yield dramatically different effects. Studies show that solutions with concentrations between 3 percent and 7 percent are typically used. However, the optimal level depends on immersion time, temperature, and grape maturity.

Higher concentrations (6–7 percent) significantly reduce drying time by enhancing skin permeability. Yet, excessive concentration can damage grape skin, resulting in wrinkling or undesirable changes in flavor and texture. A mid-range concentration of around 5 percent often achieves the best balance between improved drying performance and product quality.

Effects on Drying Uniformity and Final Product Quality

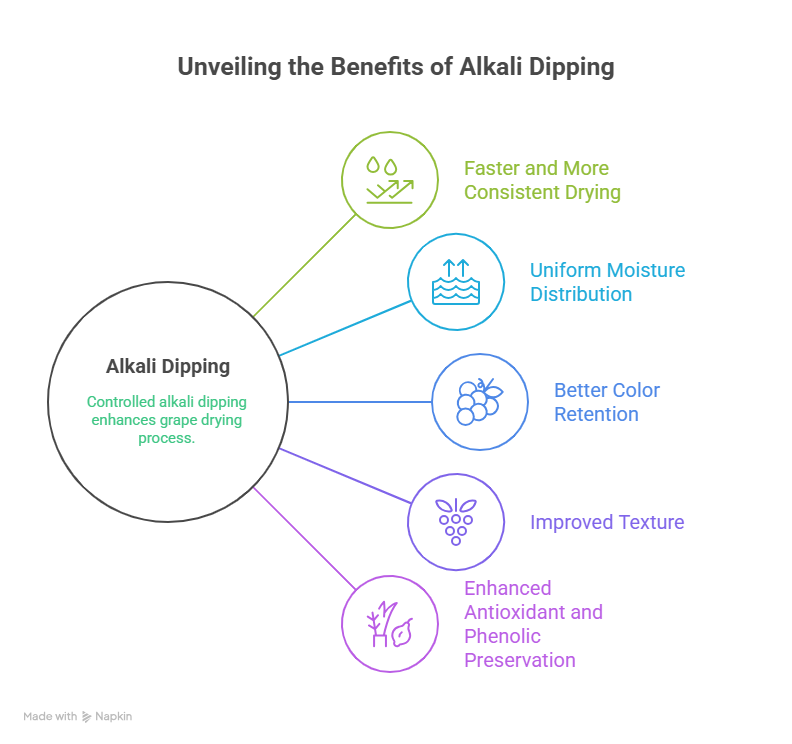

Properly controlled alkali dipping results in:

- Faster and more consistent drying

- Uniform moisture distribution

- Better retention of natural color (L*, a*, b* metrics)

- Improved texture with fewer hard or under-dried pieces

- Enhanced antioxidant and phenolic preservation compared to untreated grapes

These outcomes are not only beneficial for consumer satisfaction but also crucial for exporters and industrial buyers focused on batch reliability and minimized processing loss.

read more: Water Activity Levels in Sultana Raisins and Their Role in Mold Formation During Storage

Recommended Pre-Treatment Protocol for Sultana Raisins

1. Choose the Right Alkali Solution

Use potassium carbonate at a concentration of 4 to 6 percent. Sodium bicarbonate is also used but less effective for Sultanas.

2. Control Immersion Time

Immerse grapes for 2 to 4 minutes depending on concentration strength and grape firmness.

3. Monitor Temperature

Pre-treatment solutions work best at temperatures between 55°C and 60°C for optimal cuticle breakdown.

4. Rinse and Drain

Rinse grapes after dipping to remove excess alkali and prevent over-reaction during drying.

5. Proceed with Drying

Use consistent drying conditions (e.g. tray or tunnel dryer) to evaluate uniformity and moisture levels throughout.

FAQs

What is the best alkali concentration for treating Sultana grapes before drying?

A 5 percent potassium carbonate solution is generally effective for balancing skin permeability and maintaining quality.

Does alkali pre-treatment affect the taste of raisins?

When managed properly, it does not affect taste. Overuse or high concentrations, however, can result in bitter or harsh flavors.

How does pre-treatment improve drying efficiency?

It increases skin permeability, allowing moisture to escape faster and more evenly, reducing total drying time and energy usage