Optimal Sulfuring Duration for Golden Raisins and Its Impact on Color Uniformity

Golden raisins are prized in international markets for their bright, uniform color and smooth texture. Achieving this level of consistency, however, depends on one critical factor in the production process: sulfuring time. Should raisins be sulfured for six hours or ten? The answer is more nuanced than it may seem.

This article compares the effects of 6-hour and 10-hour sulfuring durations on the color uniformity of golden raisins. By understanding these variables, bulk buyers and producers can make better choices to meet export standards and customer expectations.

Understanding the Role of Sulfuring in Raisin Production

Sulfuring is a common step in the production of golden raisins. It involves exposing freshly harvested seedless grapes to sulfur dioxide (SO₂) gas in a controlled environment. The primary goal is to preserve the light color of the fruit, inhibit enzymatic browning, and improve microbial stability.

Sulfur dioxide reacts with polyphenol oxidase enzymes to prevent darkening, locking in the golden hue for which this raisin type is known. However, the duration of exposure significantly influences the final product’s appearance and safety.

Comparing Sulfuring Durations and Their Effects on Color

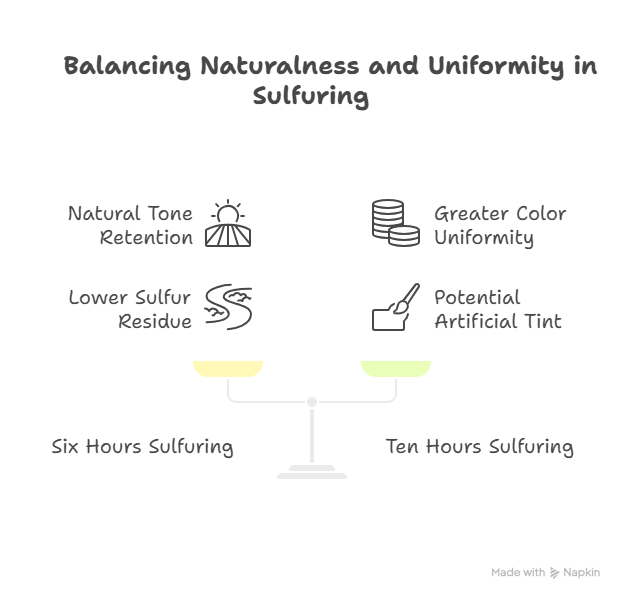

Color uniformity is essential for bulk buyers targeting high-end retail or processed food applications. Between 6 and 10 hours of sulfuring, both durations achieve color stabilization but with different outcomes.

1. Six Hours of Sulfuring

This duration is often used to retain a natural tone while reducing sulfur residue levels. It typically results in a golden yellow color with slight variation among individual raisins. Buyers favor this method when natural appearance and lower sulfur content are more important than perfect uniformity.

2. Ten Hours of Sulfuring

Prolonged sulfuring leads to greater color uniformity, with a more consistent golden appearance across batches. It is especially useful for meeting export-grade specifications where visual consistency is non-negotiable. However, overexposure may result in a slightly artificial tint and requires careful monitoring to avoid exceeding allowable SO₂ residue levels.

Industry Standards and Export Requirements

Most international markets limit residual sulfur dioxide to 2,000 ppm in dried fruit. The choice between 6 and 10 hours should be made based on the exporter’s ability to balance color consistency with residue control. For this reason, reputable producers often provide a Certificate of Analysis (COA) verifying the sulfur levels and color grading for each batch.

read more: Golden Raisin vs. Sultana: What’s the Real Difference?

Choosing the Right Sulfuring Duration for Your Needs

Producers should consider market preferences, buyer expectations, and regulatory requirements before finalizing their sulfuring protocols. For buyers, asking about sulfuring duration during negotiations helps ensure they receive products that meet specific visual and safety standards.

Frequently Asked Questions

What is the purpose of sulfuring golden raisins?

Sulfuring prevents enzymatic browning and maintains the golden color by inhibiting oxidation and microbial activity.

Which duration provides better color uniformity—6 or 10 hours?

Ten hours generally offers more uniform color but may increase SO₂ residue, while six hours maintains a more natural appearance with slight variation.

Does sulfuring affect the safety of raisins?

When performed within international limits, sulfuring is safe. Producers must monitor and certify sulfur dioxide levels to comply with food safety regulations.